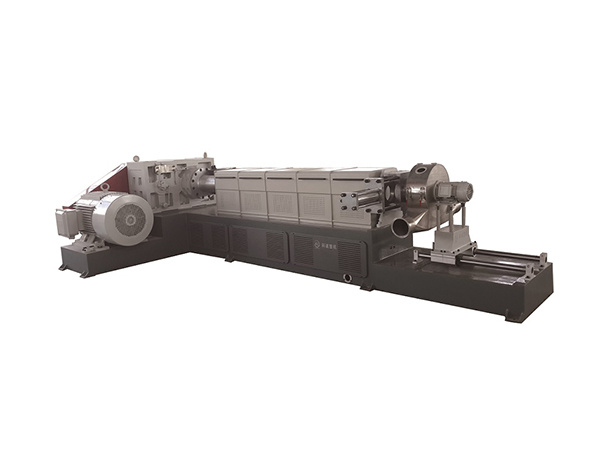

single screw extruder

Product Classification:

Key words:

Packing Machine | Internal Mixer | Granulator |

Product price:

Contact:

Product Details

Single screw extruder is a common extruder equipment used in the plastic raw material and profile extrusion processing industry. Usually the single-screw extrusion of the screw is divided into the conveying section of the extruder, compression section, metering section; according to the size of the screw diameter, pitch, depth to determine the effective length of the three sections, generally according to the 1/3 of division. The last thread of

material port starts to call the conveying section material not plasticized here, but it needs to be preheated and compacted. In the past, the old extrusion theory believed that the material here was a loose body. Later, it was proved that the material here was actually a solid plug, that is to say, the material here was a solid like a plug after being squeezed. Therefore, as long as the conveying task was completed, it was its function. Principle of

Single Screw Extruder: When the second section is called compression section , the volume of the screw groove gradually decreases from large to small, and the temperature should reach the plasticization degree of the material. The compression generated here is from conveying section 3 to one, which is called the compression ratio of the screw (3 : 1 ). Some machines also change, and the plasticized material enters the third section. Principle of

Single Screw Extruder: The third section is the metering section . The material here keeps the plasticizing temperature, only conveying the melt material accurately and quantitatively like a metering pump to supply the head. At this time, the temperature cannot be lower than the plasticizing temperature, which is generally slightly higher.

Kecheng's single screw is mainly used in raw material mixing and extrusion. Compared with the extrusion machine for profile extrusion, its diameter requirement is larger and the screw requirement is longer, so as to better mixing and plasticizing.

Nantong Kecheng is committed to the research and development, production and sales of efficient internal mixing unit, dense extrusion granulating unit, twin screw granulating unit, single screw granulating unit, double step granulating unit, profile extrusion unit, experimental unit, etc. Kecheng's units are widely used in cable materials, high-filling masterbatch, black and white masterbatch, masterbatch, recycled materials, engineering plastics, general plastics, elastomers, sheet profiles and other fields. We warmly welcome customers, industry experts to visit the company.

Key words:

单螺杆

塑料

CONSULTING CONTENT

Note: Please leave your email and our professionals will contact you as soon as possible!