Carbon black masterbatch/white masterbatch

Product Classification:

Key words:

Packing Machine | Internal Mixer | Granulator |

Product price:

Contact:

Product Details

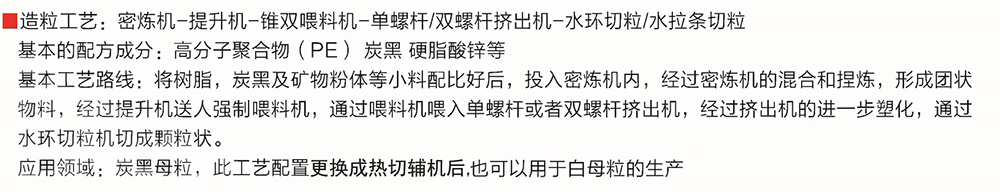

Nantong Kecheng is committed to the research and development, production and sales of efficient internal mixing unit, dense extrusion granulating unit, twin screw granulating unit, single screw granulating unit, double step granulating unit, profile extrusion unit, experimental unit, etc. Kecheng's units are widely used in cable materials, high-filling masterbatch, black and white masterbatch, masterbatch, recycled materials, engineering plastics, general plastics, elastomers, sheet profiles and other fields. We warmly welcome customers, industry experts to visit the company.

Key words:

炭黑

白母粒

CONSULTING CONTENT

Note: Please leave your email and our professionals will contact you as soon as possible!