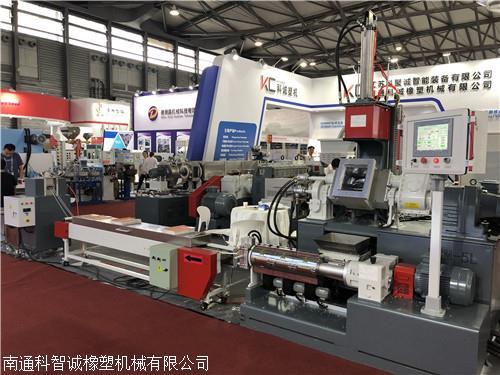

silicone rubber granulator

Product Classification:

Key words:

Packing Machine | Internal Mixer | Granulator |

Product price:

Contact:

Product Details

| Brand | Ke Zhicheng | Model | 150 |

| Processing Customization | Is | Origin | Other |

| Imported | No | Host Power | >90KW |

| production capacity | <500 Kg/h | granulation diameter | 5mm |

| granulation rate | >99% | overall dimensions | other |

| weight | 5000kg | screw diameter | 150mm |

| SCREW Aspect Ratio | 9:1 | Die Type | Air-cooled Die Surface Hot Cutting Head |

| Cutter Speed | 1480r/min | Pelletizer Power | 2.2kW |

| Manufacturer | Nantong Kezhicheng |

silicone rubber (Q) as the main chain containing silicon, oxygen atoms of special rubber, among them, the silicon element plays a major role. Its main characteristics are high temperature resistance (* high 300 ℃) and low temperature resistance (* low -100 ℃), and it is currently a cold and high temperature resistant rubber. At the same time, it has excellent electrical insulation, high stability to thermal oxidation and ozone, and large chemical inertness. The disadvantage is that the mechanical strength is low, oil resistance, solvent resistance and poor acid and alkali resistance, more difficult to vulcanize, the price is more expensive. Use temperature:-60 ℃ ~ +200 ℃. Mainly used in the production of high and low temperature resistant products (hose, seals, etc.), high temperature resistant wire and cable insulation layer, because of its non-toxic and tasteless, but also used in food and medical industry. The main raw materials of rubber products are raw rubber, various compounding agents, and fiber and metal materials as skeleton materials. The basic production process of rubber products includes 6 basic processes of plastication, mixing, calendering, extrusion, molding and vulcanization. The processing process of

silicone rubber granulator is mainly to solve the contradiction between plasticity and elasticity. Through various processing methods, elastic rubber is turned into plastic rubber with plasticity. After adding various compounding agents to make semi-finished products, the semi-finished products with plasticity are turned into rubber products with high elasticity and good physical and mechanical properties through vulcanization.

silicone rubber granulator is through the role of the barrel wall and screw parts of the extruder, so that the rubber material to achieve the purpose of extrusion and preliminary modeling, extrusion process has also become the extrusion process.

The main equipment of the extrusion process is a silicone rubber granulator.

The extrusion characteristics of several rubbers: natural rubber has a fast extrusion speed and a low shrinkage rate of semi-finished products. Body temperature: 50-60 ℃, nose temperature: 70-80 ℃, mouth shape: 80-90 ℃; Slow extrusion speed of styrene-butadiene rubber, large compression deformation, rough surface, body temperature: 50-70 ℃, nose temperature: 70-80 ℃, mouth temperature: 100-105 ℃, mouth 90-140 ℃. NBR has poor extrusion performance and shall be fully heated during extrusion. The fuselage temperature is 50-60 ℃, and the nose temperature is 70-80 ℃.

Nantong Kecheng is committed to the research and development, production and sales of efficient internal mixing unit, dense extrusion granulating unit, twin screw granulating unit, single screw granulating unit, double step granulating unit, profile extrusion unit, experimental unit, etc. Kecheng's units are widely used in cable materials, high-filling masterbatch, black and white masterbatch, masterbatch, recycled materials, engineering plastics, general plastics, elastomers, sheet profiles and other fields. We warmly welcome customers, industry experts to visit the company.

Key words:

橡胶

硅

CONSULTING CONTENT

Note: Please leave your email and our professionals will contact you as soon as possible!